Automation?

With warehouse automation expected to grow by around 15% in the next year, many of the largest Australian retail and logistics companies are starting to invest six-and-seven-figure sums into smart warehouses, many with an automated storage and retrieval system. They understand that efficiency is key and that they need to upgrade their racking systems to accommodate all the possible advances in the industry. Similarly, have you started noticing more frequent repairs and maintenance needs, indicating it might be time to renew your warehouse racking system?

The following article will help you recognise when it’s time to upgrade. It will also provide information on up-to-date pallet racking for businesses and explain why simply optimising warehouse layout may not be enough. Finally, it will discuss modern storage solutions and explain why today is the time to investigate an upgrade.

Frequent Repairs and Maintenance

Regular maintenance is essential for ensuring your pallet racks remain functional. Neglecting it can lead to structural issues and an increased likelihood of accidents.

To combat this, a scheduled maintenance plan can help proactively discover and resolve these issues before they escalate. However, if the problems that require action become more frequent than said schedule, it may be due to the age and general wear of the equipment.

These unscheduled stoppages also lead to an inability to continue with work. Your clients may then no longer trust you to complete your tasks in the allotted time, leading to further losses as they cancel contracts.

Without action, these repairs can start to add up, leading to:

- Slowdown in your throughput

- Increases in outgoings due to repair costs

- Reductions in profits from delays

- Reputational damage

One significant benefit of a storage upgrade is that it will renew the life of all your pallet racking, meaning that it no longer suffers from the wear and tear of the old system. Any updated systems will also have newer, more advanced, and higher-quality materials and components, further reducing the frequency with which you need to take action.

Safety Concerns

Improving your storage system doesn’t only mean enhancing your warehouse operations. With the number of workers suffering from fatal injuries rising in recent years, it is paramount that you take action to protect employees and assets.

An older racking set can pose increased safety risks. In some circumstances, it can even create the potential for a complete collapse, causing untold harm to employees and assets. When regular inspections identify signs of such instability, especially when they no longer comply with Australian safety standards, you must update your racks to reduce the likelihood of incidents occurring.

Taking this step also contributes to a better workplace safety culture. With over one million serious workers’ compensation claims made in the past ten years, increasing safety is not only a good idea but also a way to directly prevent such losses and save you money.

Insufficient Storage Capacity

Nobody has infinite space, but changing equipment or stock sizes over time can often lead to a poorer use of the space you do have. As your business grows, you need to increase the volume of your pallet storage solution and find ways to use what you have more efficiently.

Review your inventory levels regularly to ensure you optimally use your available space. Then, audit your storage methods to determine whether your pallet storage methods use as much of the rack as possible. If either of these is not true, you might want to start improving your storage system to create a more dynamic storage solution.

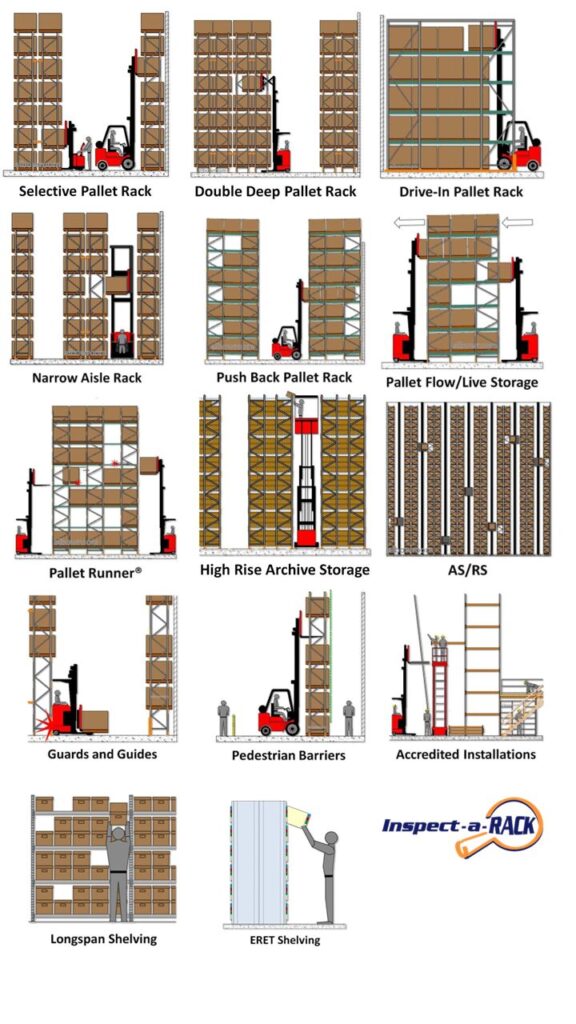

Investing in a scalable storage solution allows you to be more flexible. After all, there is only so much that even the best pallet-racking efficiency tips can do before you must overhaul the whole process. Triple or dual-purpose pallet racking can help by offering:

- Adjustable shelving to store different sizes of items

- Modular shelving structure to enable easy reconfiguration

- Selective racking for easy access to pallets

- Drive-in racking for simpler storage

Determine which specific solutions are best for you. Then, investigate pallet racking options that match as many of your unique needs as possible.

Workflow Bottlenecks

Significant material flow bottlenecks are common when using outdated racking systems due to their size, shape, and the need for specific safety equipment to navigate or secure them. Similarly, a long legacy of updates and changes to your warehouse can cause unnecessary congestion in specific high-traffic areas. Each of these can start to slow down movement within the warehouse and create problems further down the supply chain, further impacting fulfilment.

Working with a racking expert, you can investigate the possibility of more efficient workflow planning, updating and upgrading your pallet racking. They will look at:

- The physical racks you are using

- The layout of the racks

- Whether staging areas for inbound and outbound goods will help

- How best to include technological innovations in your process

Doing this can ensure that travel time is as short as possible, helping workers store and retrieve material faster without impeding others.

Leveraging an Automated Storage and Retrieval System

If you do not already use real-time inventory tracking and automated storage systems, it may be time to upgrade. Modern warehouses use these systems to quickly identify where stock is and whether you need to order more to compensate for a low quantity in storage, then collect it for use when it is available. Such a system even prevents time wasted searching for items that may not even exist, boosting your process in other areas of the business.

Upgrade Your Pallet Racking for a More Efficient Future

Moving to a fully automated storage and retrieval system may be outside your scope. However, outdated pallet racking systems can lead to several other challenges. So, work with a pallet racking specialist to ensure you have everything you need to streamline operations.

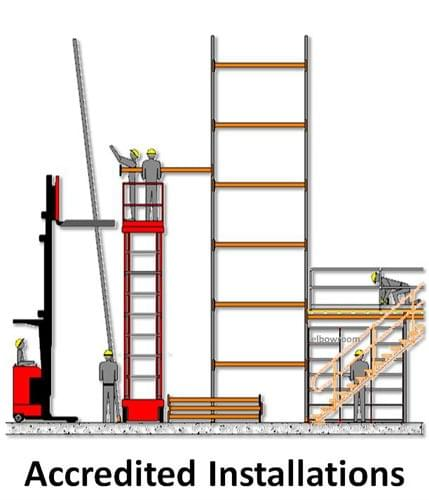

Elbowroom can offer modern racking solutions that ensure compliance with Australian safety standards and boosts productivity. With decades of experience, we can help you find something that will improve your process for years to come and assist with a regular maintenance plan. Contact us to speak to our pallet racking solutions specialists and discover what to do next.