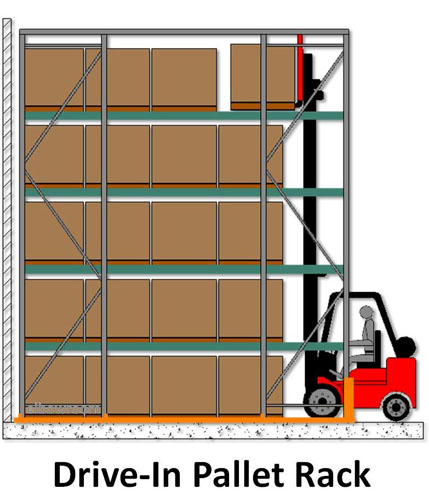

When it comes to optimising warehouse space, drive-in pallet racking systems offer a compelling solution for high-density storage. A client named Graeme contacted us seeking a drive-in pallet rack capable of accommodating 1,000 pallets. Instead of jumping straight to a quote, we opted to ask detailed questions to better understand Graeme’s specific requirements and operational constraints. This approach is crucial because while drive-in racking is renowned for its dense storage capabilities, it isn’t always the best fit for every inventory scenario.

For instance, Graeme’s warehouse faced limitations with his current selective rack layout, and he was advised that drive-in racking would solve his space issues. While drive-in racks indeed offer more storage density compared to selective racks, their suitability depends heavily on the nature of the inventory. Graeme’s warehouse had a high number of SKUs with relatively low inventory per SKU, which posed a challenge for drive-in racking due to its Last-In, First-Out (LIFO) operation. Instead of drive-in racks, we recommended modifying his existing setup by converting some racks to double-deep and adding new racks to better accommodate his diverse inventory.

Key Considerations for Drive-In Pallet Racking

Drive-in pallet racking systems are designed for maximum density, making them ideal for warehouses with a limited number of SKUs and high inventory per SKU. For example, if Graeme’s inventory had only six SKUs, each with 25 pallets, drive-in racking would be highly efficient. However, for a higher SKU count with lower inventory levels, such as Graeme’s case, other solutions might be more appropriate.

When designing a drive-in rack system, the depth of the lanes is a critical factor. While Australian brands like Colby adhere to stringent engineering standards, the practical depth of drive-in lanes is determined by the specific needs of the inventory, including stock turnover rates and warehouse operations. Generally, drive-in racks require careful planning to avoid low occupancy rates, which often hover around 65%-75% due to the LIFO system and potential inefficiencies in stock movement. For example, if Graeme needed to store 1,000 pallets with an average occupancy rate of 70%, he would require around 1,429 pallet positions.

To address these challenges, integrating a mix of racking systems, such as drive-in, double-deep, and selective racks, can optimise storage efficiency. A well-designed system can achieve occupancy rates of 85%-90%, balancing the need for high-density storage with practical operational considerations.

Challenges and Limitations of Drive-In Pallet Racking

While drive-in racking offers significant advantages in terms of space utilisation, it is not without its limitations. One major challenge is the LIFO operation, which can complicate stock rotation. Drive-in racks are not naturally suited for environments requiring FIFO (First-In, First-Out) stock management. Additionally, each lane in a drive-in rack is typically dedicated to a single SKU, limiting selectivity and potentially leading to inefficient use of space if not managed carefully.

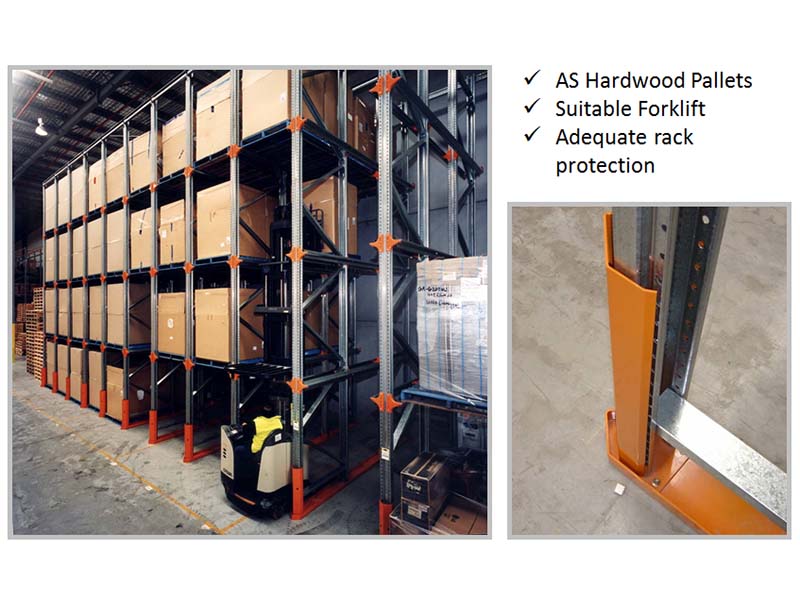

The type and condition of pallets used in drive-In racks are crucial. Only pallets that meet the specifications set by the rack manufacturer should be used to ensure safety and functionality. Damaged or incompatible pallets can compromise the integrity of the racking system. Drive-in racking systems require specific forklift trucks designed for their operation, and forklift drivers need to exercise greater care and skill to avoid damaging the racks.

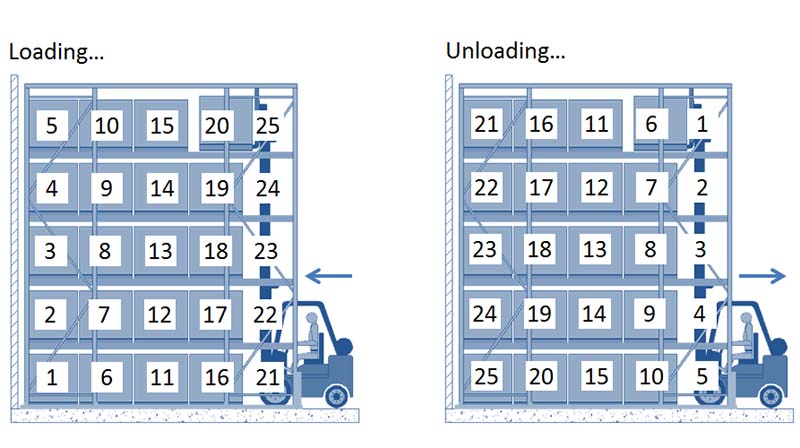

Correct Loading and Unloading Sequences for Drive-In Racks:

While drive-in pallet racking can be an excellent solution for certain storage needs, it is essential to evaluate its suitability based on inventory type, operational requirements, and space constraints. For personalised advice and solutions tailored to your warehouse, contact the experts at Elbowroom today. We offer delivery across Australia, providing professional support for all your racking needs.